Augustus 2018,

The company Heck is moved to Zwaagdijk-West.

This location is directly situaded next to the A7 moterway.

In this excisting building, comes our Office, as well as a bigger warehouse and space for assembling your valves and actuators.

1686 PJ Zwaagdijk-West

The Netherlands

Tel. +31(0)85 - 049 2020

2015

For the expansion by Albemarle (Catalyst) in Amsterdam we delivered six screw conveyers. Two of this screw converyers are made from very corrosion resistant Hastelloy C276 material. In consultation with the client there is chosen for this material because of the high temperature and chemical composition of this product.

2015

Because of very good experience with a few of our costumers with liners of the company Powertex we decided to be there representative in the Nehterlans and Belgium. A bulk container liner is a prefabricated bulk lining system installed in a 20 foot or 40 foot intermodal container and is utilized for the transport of dry flowable products. All bulk container liners and bulk bags are available in various types of materials. We would be glad to do any test with your materials.

2015

We are pleased to inform you that we expanded our coöperation with the company Euba-Antriebtechnik Eller Gmbh. Already since 1999 representative in the Netherlands we know also will be your contact for Belgium.

2014

As of 1 September, our compagnies, Industriële handelmaatschappij Heck and Technisch Bureau Heck merged and we continue under the name Technisch Bureau Heck BV. From the history our company worked with two compagnies, founded in respectively 1965 and in 1953. By constant changing working practices and market, we have chosen for simplification and cost savings.

The Chamber of commerce and VAT number wil be changed, the rest will remain unchanged.

2013

In the harbour of Antwerp with the company Sea-invest we delivered for the company Imerys an complete pneumatic conveying system to feed three vertical cylindrical silos from each 800 m3 with dry kaolin powder.

This instalation from Dynamic Air ltd, complete with surge-hopper, transporter, conveying line, Modu-kleen filter system and the complete pneumatic- and electrical control system is designed for 15000 kg/hour with an lowest possible air consumption.

2013

On the Power plant from the company E-On based on the Maasvlakte we revised both the dedusting units 1 and 2, from the coal hoppers delivered original in 1986. The complete filter heads with filter plates, retaining cages, filter bags and rotary valves are replaced. These filters are located on the top of the roof on a height of 55 meters. This project is done completly turnkey.

2012

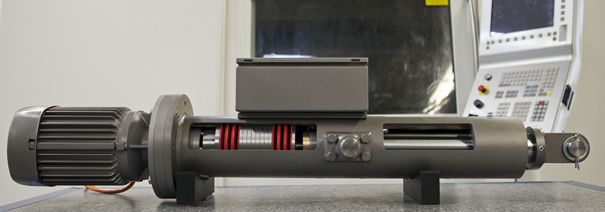

On the gas fired Power plant from the company Nuon, location Velsen-Noord, we delivered and mounted 8 electric actuators from the company Euba. Complete with connections, housing, deposal, de- and mounting, testing and commissioning.

These electric actuators with a stroke of 600 mm are for the control of the air and smoke valves, located inside as well as outside.

2011

Overhauled at the "Hoogovens" of Tata Steel IJmuiden, the explosion repressive system of the daily used central vacuum cleaning system. This system of the company Beth is equipped with two quick close gatevalves and two pressure detectors. As the system was build in 1983, there were not enough spare parts available for the control unit. It was decided to place a new control unit with two new pressure detectors. The two quick close gatevalves are revised and brought in new state. Along with new cabling and an operational test the installation is ready to work safely again.

2010

Delivered in the south east of the Netherlands. An BETH electrostatic Precipitator for dedusting of an biomass (wood) fired boiler. Demants for emission <5mg/m3.

After measurements in process this is no problem, measure gives 1,6 mg/m3 by actualgas, this gives in normgas 2,6 mg/m3 (6% Vol. O2 dry).

Design conditions from this filter:

- Flow : max. 58.000 Nm3/h

- Temp. : 235°C tot 290°C,

- Pressure loss filter : < 4 mbar

- Hightension : 70 kV, 500 mA.

2010

Three new contracts for ThyssenKrupp Fördertechnik Gmbh at EMO Dry Bulk Terminal in the port of Rotterdam,

For the company EMO, the largest company in Europe for bulk goods (coal and iron ore) Thyssenkrupp Fördertechnik currently builds the following 3 machines for enlargement of the capacity,

A Wagon Loading Station of railwagon, this loading station will be put into operation in mid-2011.

A Stacker-reclaimer, for the supply of the Power plant, currently under construction from the company Electrabel, which will be operational in 2012.

Furthermore, the largest grab Unloader in the world (85T), with a span of 70 m and an outreach of 50 meters above the waterside. See the picture below.

Januari 2009, we have expand our delivery program with the representation of the company DYNAMIC AIR Ltd.

DYNAMIC AIR Ltd. manufactures complete pneumatic conveying systems and has some very prestigious projects at renowned manufacturing companies all over the world.

Oktober 2007, Airslide installation for Cleeve(Lafarge) in the UK. Complete airslide installation with divers shut-off valves.

Oktober 2007, Airslide installation for Cleeve(Lafarge) in the UK. Complete airslide installation with divers shut-off valves.

Juni 2006, delivered, aeration bottem for silo 30 x 60 meter with airslide installation 200 t/h, bulkstorage of alumina.

© Copyright HECK B.V.